Environmental policy

We’re working hard to minimise our impact on the environment – and that means putting serious effort into the things that are out of sight too.

There’s always more to do. But we’re really proud that we do more than most.

Made to last

Our products are designed to a quality standard, not to a price.

This means we use processes and materials that are significantly better than industry standards to create products that’ll endure.

Our lights are a good example.

Rather than making lights with built-in LED chips (a common approach in the industry), we engineer ours so they look great and use standard bulbs.

This means when your LED eventually reaches the end of its lifespan, instead of replacing the entire light fixture, you just need to change the bulb.

Circular economy

Where we use plastic to manufacture our products, we use a mix of new and fully recycled post-consumer types.

The recycled plastic we use is innovatively formed from waste bottle lids, screw caps and the like. It’s more expensive, it’s harder to use and it’s the result of a lot of development. It’s not the norm in the industry (in fact, it’s really rare), but it’s normal for us.

It’s also GRS (Global Recycled Standard) 4.0-certified, which means the recycled content’s been verified, and responsible social, environmental and chemical practices are used in the process.

In 2023, 9% (1.1 tonnes) of the plastic we used was the recycled type. So far in 2024, we’ve increased that amount considerably to 73% (9.5 tonnes).

Almost all our other products are made from solid brass, a durable metal that will last a lifetime. It’s also an infinitely recyclable material.

Plastic-free packaging

From the very beginning, we’ve never used plastic in our packaging – it’s one of our core standpoints. But sending delicate items using only cardboard is a challenge.

We’ve created our own cardboard structures to protect our products in the best, and most responsible, way.

They’re designed and cut with advanced CNC box cutting machines (a tool usually used to make precise bespoke boxes). Again, it’s not something you’ll come across very often in the industry.

Our products are wrapped in tissue paper to protect them from scratches, and the boxes are sealed with water-activated paper tape.

How you can recycle our packaging

Our packaging can be recycled where infrastructure and access to paper and cardboard recycling exist.

Recycling rules vary between countries, regions and areas. We encourage you to check with your local authority to find out how to correctly dispose of our recyclable packaging.

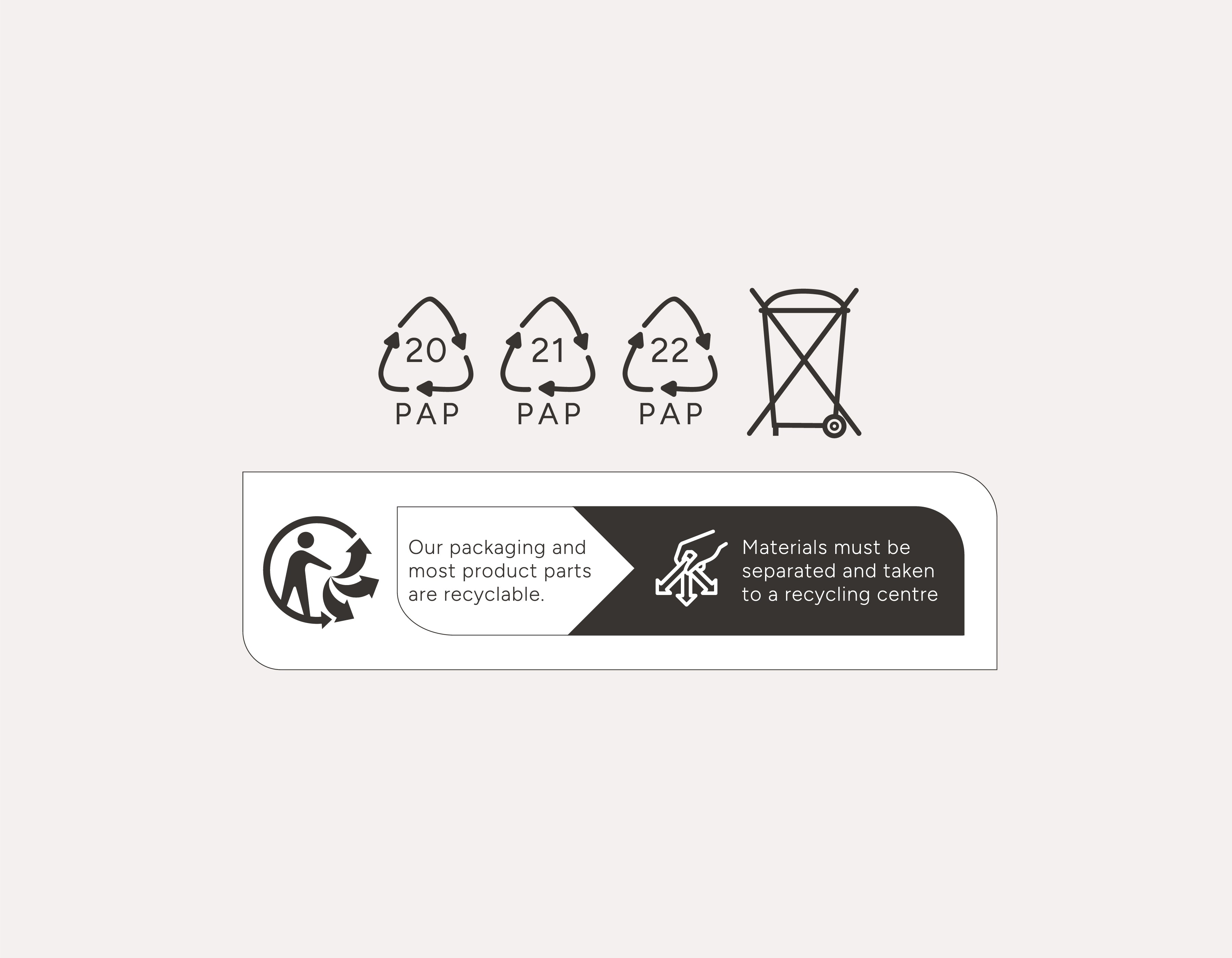

Material identification codes

Our packaging features recycling codes (triangular symbols with chasing arrows).

The codes show that our boxes are made of cardboard (PAP 21) and, to increase the structural integrity of the boxes for transport in some cases, corrugated cardboard (PAP 20). PAP 22 means there will be paper-based packaging inside the box.

PAP 20, 21, and 22 materials are widely recyclable.

Electrical products and batteries

Electrical items and batteries should be disposed of separately from other types of waste (a requirement by EU legislation)

We encourage you to check with your local authority to find out how to correctly sort and dispose of these items.

How we recycle our own packaging

We’ve invested in our own cardboard crushing machine to make bales of clean, dry recyclable cardboard. We sell these bundles to the market to be used again. We also use a local company to recycle our excess pallets.

As a whole, we contribute less than one tonne of bulk plastic to the waste stream each year.

Our purpose built HQ

We designed and built our own head office ourselves to a high eco specification.

It’s insulated way beyond benchmark standards, it’s heated and cooled with solar assisted heat pumps, and the solar panels on our roof generate up to 110kW of electricity.

All in all, it’s a really low-energy space to run.

CO2

In 2022, we planted four acres of native woodland at our original Wiltshire HQ (we’ve since moved a stone’s throw away). Using Woodland Carbon Code methodology, it’s estimated that our trees and shrubs will capture 600 tonnes of CO2 over the next 100 years.

Last-mile deliveries

Around 20% of our orders are delivered by electric vehicles. It’s a percentage that will continue to grow as the technology develops.